Special Purpose Pasta Making Machine

Our Pasta Making Machine range now includes advanced special purpose models designed to produce a variety of innovative pasta types. Whether you need a Millet Pasta Making Machine, a Ragi Pasta Machine, or a Rice Pasta Machine, we offer customized solutions that help you meet the growing demand for healthy and gluten-free pasta products.

Built with precision and durability, these machines can manufacture a wide range of pasta shapes and recipes, including Millet Noodles, Rice Pasta, Butterfly Pasta, Gnocchi, Lasagne Pasta, Instant Pasta, and Gluten-Free Pasta. Each model is engineered for maximum output, consistent product quality, and easy operation.

Our equipment is also ideal for producing traditional short-cut pasta varieties and can be configured as a Macaroni Making Machine or a Butterfly Pasta Machine depending on your production needs.

If you’re planning to diversify into health-focused or specialty pasta markets, our special purpose Pasta Making Machines provide the perfect foundation for your success.

SPECIAL PURPOSE PASTA MAKING MACHINES

Gluten-Free Pasta Production Line

At KP Automations, we specialize in manufacturing advanced processing systems for modern food production. Our Gluten-Free Pasta Production Line is meticulously engineered to handle the complexities of non-gluten ingredients such as rice flour, corn flour, quinoa, and millet. This turnkey solution integrates the Gluten Free Pasta Machine with automated stages including premixing, extrusion, shaping, drying, and packaging. Each component is built to ensure smooth handling of gluten-free dough, which requires different processing parameters compared to traditional semolina-based pasta.

Applications of the Gluten-Free Pasta Line

The Gluten Free Pasta Line is suitable for:

- Commercial and industrial pasta manufacturing units

- Health and specialty food producers targeting allergy-sensitive markets

- Export-focused manufacturing plants adhering to global food safety standards

This line supports the production of multiple pasta formats such as penne, fusilli, macaroni, spaghetti, and short-cut extruded pasta – all gluten-free.

Key Technical Features of the Gluten Free Pasta Machine

- Hopper-fed automatic dosing system to maintain batch consistency

- Interchangeable pasta dies and cutters for versatile shape production

- Hot air circulation drying tunnels with PID temperature control for moisture regulation

- 304/316-grade stainless steel construction for food-grade hygiene compliance

- Automated cleaning and safety interlock systems to reduce downtime and ensure operator safety

Benefits of the Gluten-Free Pasta Making Machine

Optimized for Non-Gluten Inputs – The Gluten Free Pasta Making Machine is tailored to process gluten-free flours that lack natural binding strength, using custom screw designs and controlled thermal profiles.

High-Throughput Output – Suitable for 100 kg/hr to 500 kg/hr production capacities depending on configuration – scalable as per business growth.

Precision Extrusion and Drying – Maintains shape integrity and desired al dente texture, even with sensitive ingredients like rice or millet flour.

Easy Maintenance and Compliance – Designed for easy disassembly and cleaning, with materials and surfaces meeting HACCP and FSSAI standards.

Energy-Efficient Operation – Our pasta line features energy – saving motors and insulation systems to optimize power consumption and reduce operational cost.

Whether you’re a food startup entering the gluten-free market or an established manufacturer looking to expand your product range, our Gluten Free Pasta Production Line offers the reliability, scalability, and efficiency you need to succeed in a health-driven industry.

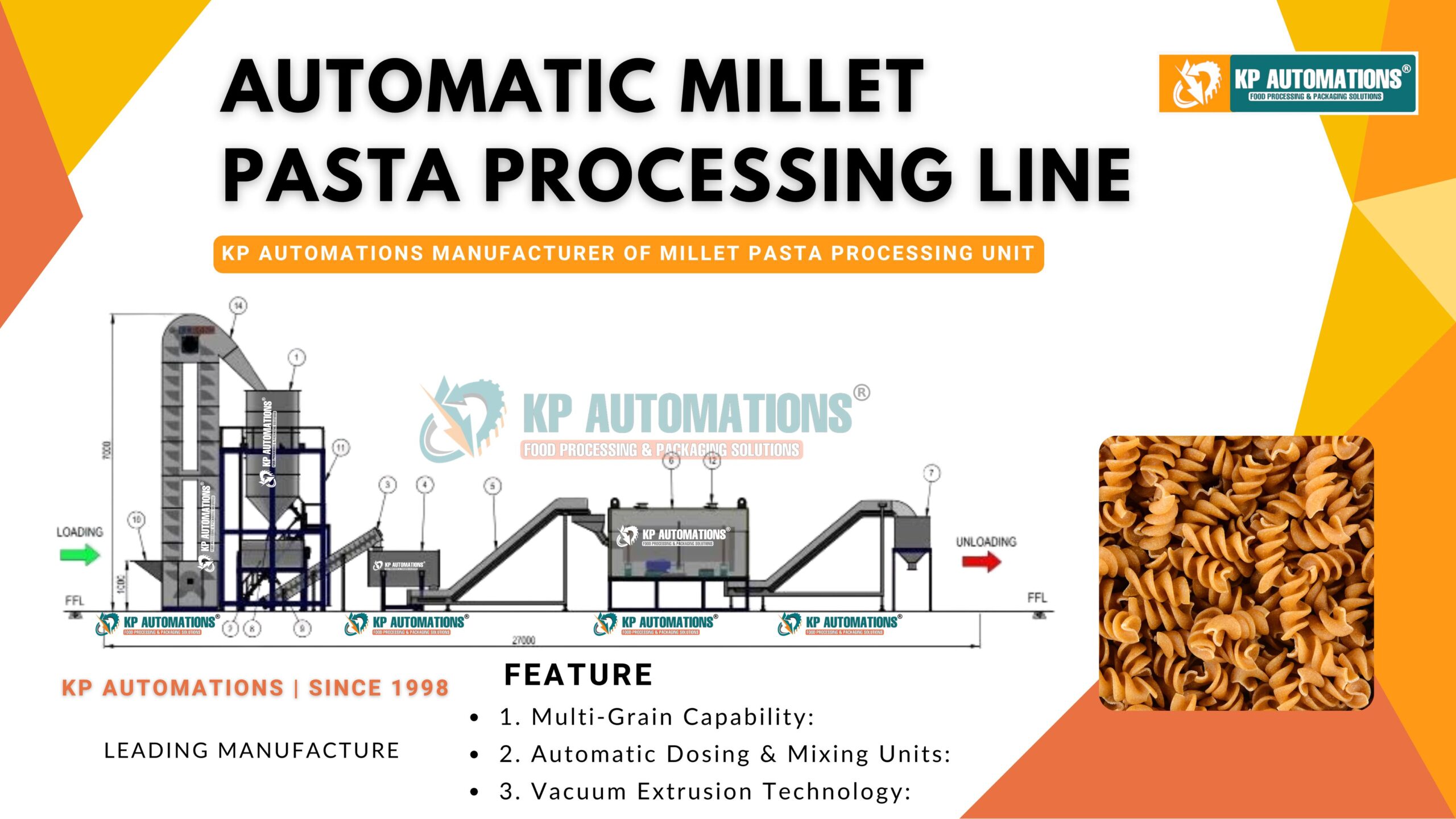

Millet Pasta Processing Line

Our Millet Pasta Processing Line is specially designed to manufacture high-quality, nutritious pasta from a variety of millets such as ragi, bajra, and jowar.

Built for today’s health-conscious consumers, this line offers a fully automated process – from dough preparation to extrusion and drying – ensuring consistent taste, texture, and shelf life.

The line is equipped with a precision-engineered Millet Pasta Making Machine that handles the unique properties of millet flours, delivering perfectly shaped pasta with excellent cooking performance.

It is ideal for manufacturers looking to enter the growing gluten-free and health food markets.

.

Key Features of the Millet Pasta Machine

- Heavy-duty Pasta Making Machine suitable for millet, multigrain, and blended flour doughs

- Food-grade stainless steel construction ensuring hygiene and durability

- Automatic extrusion, cutting, and drying operations

- Customizable die designs for different pasta shapes and sizes

- Energy-efficient processing with minimal maintenance requirements

- Designed for easy cleaning and product changeover

Our Millet Pasta Making Machine and complete Pasta Machine setup are the perfect choice. Take advantage of the booming health food sector with consistent, high-quality millet pasta products!

Applications of the Millet Pasta Line

The Millet Pasta Processing Line is used for producing a variety of pasta products made from millet, including:

- Gluten-free pasta varieties

- High-fiber and high-protein pasta

- Specialty health-focused pasta for diet and nutrition markets

This setup can be customized further based on specific millet types and recipe requirements, giving you complete flexibility in product development.

Ragi Pasta Processing Line

Our Ragi Pasta Processing Line is designed for the efficient production of healthy and gluten-free pasta made from ragi (finger millet). With increasing consumer demand for nutritious and functional foods, investing in a dedicated Ragi Pasta setup can give your brand a strong competitive edge.

This line covers every stage of production – from dough preparation to extrusion, cutting, and drying – ensuring consistent quality and taste.

At the heart of the system is our specialized Ragi Pasta Machine, engineered to handle the unique characteristics of ragi flour.

Key Features of the Ragi Pasta Making Machine

- Heavy-duty Ragi Pasta Machine built for millet and multigrain doughs

- Complete automation from mixing, extrusion, shaping, to drying

- Food-grade construction ensuring safety and hygiene

- Easy integration with other Pasta Making Machines for diversified production

Our Ragi Pasta Machine and related Pasta Making Machines provide the ideal solution to produce high-quality ragi pasta with efficiency and consistency.

Benefits of Ragi Pasta Making Machine

Our Ragi Pasta Processing Line offers numerous advantages for pasta manufacturers aiming to produce healthy, gluten-free alternatives:

- Consistent Product Quality – The specialized design ensures uniform dough mixing, extrusion, and drying, resulting in consistent texture, color, and cooking performance in every batch.

- Flexibility in Production – Easily produce different pasta shapes and recipes by integrating additional modules or dies, expanding your product offerings without needing new Pasta Making Machines.

- High Efficiency and Low Wastage – The automated process minimizes material wastage and human error, ensuring cost-effective production even at larger scales.

- Food Safety and Hygiene – Constructed with food-grade stainless steel and designed for easy cleaning, our machines ensure compliance with strict hygiene standards.

- Scalable for Business Growth – Whether you’re starting small or planning for large-scale operations, the Ragi Pasta Processing Line can be scaled up easily to match your business needs.

Millet Noodles Pasta Processing Line

Our Millet Noodles Pasta Processing Line is designed for the seamless production of millet-based noodles and pasta varieties. With the rising trend of gluten-free and health-focused foods, this line allows manufacturers to tap into new markets by offering nutritious, millet- based products.

From mixing to extrusion and drying, every stage is fully automated to ensure consistent quality, taste, and shelf life. The line is powered by a specialized Millet Noodle Pasta Machine, which handles millet flour efficiently, maintaining the natural nutrients and achieving perfect texture in every strand. It’s an ideal solution for businesses looking to diversify into healthy noodle and pasta products.

Key Features of the Millet Noodles Pasta Making Machine

- High-performance Millet Noodle Making Machine for smooth

- Food-grade stainless steel construction ensuring safety and hygiene

- Adjustable dies and molds for different noodle and pasta

- Compatible with additional Noodle Making Machine and Pasta Making Machine setups for future expansion

With our Millet Noodle Pasta Machine and advanced Pasta Making Machine line, you can confidently produce high – quality, nutritious millet noodles and pasta, helping your brand stand out in the fast-growing healthy foods segment.

Benefits of Millet Noodles Pasta Making Machine

Choosing our Millet Noodles Pasta Processing Line provides several advantages for manufacturers aiming to capture the growing health and wellness market:

Superior Product Consistency – The line ensures uniform dough mixing, extrusion, and drying, resulting in consistent texture, taste, and cooking quality across all batches.

High Production Efficiency – Our fully automated Millet Noodle Making Machine minimizes manual intervention, reduces labor costs, and increases production capacity without compromising on quality.

Food-Grade Safety Standards – The use of stainless steel and hygienic design ensures your products are processed in a clean and safe environment, meeting international food safety regulations.

Scalable and Future-Ready – Easily integrate additional Noodle Making Machine or Pasta Making Machine setups as your production needs grow, making your investment future-proof.

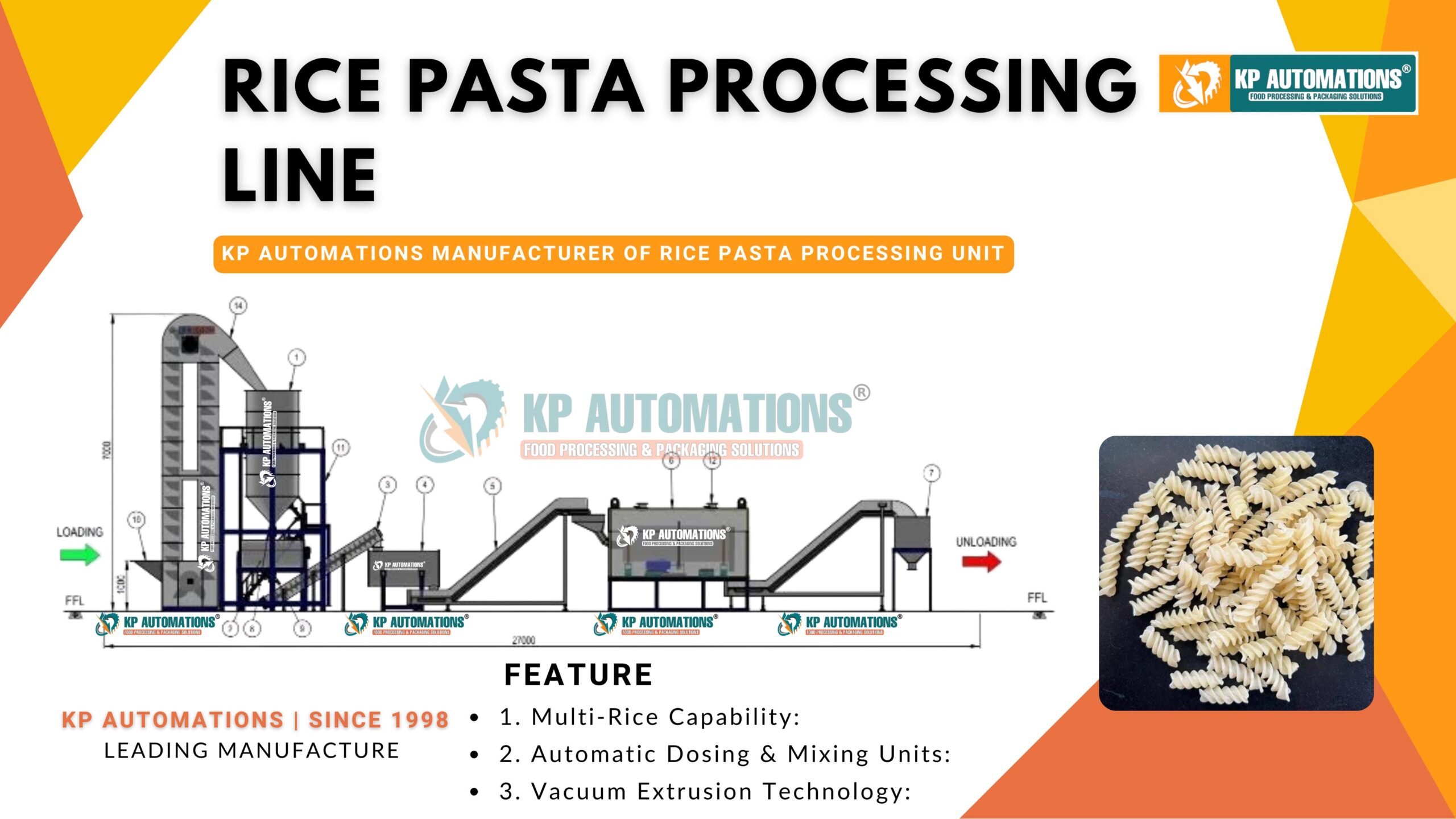

Rice Pasta Processing Line

Our Rice Pasta Processing Line is designed specifically to produce premium-quality rice pasta, meeting the rising demand for gluten- free, healthy food options. This complete setup covers all essential stages — mixing, extrusion, cutting, and drying — to produce rice-based pasta with excellent texture, taste, and shelf life. Rice Pasta Making Machine, engineered to handle the delicate nature of rice flour while delivering consistent pasta shapes and smooth operation.

Key Features of the Rice Pasta Making Machine

- Specialized Rice Pasta Making Machine for optimal extrusion of rice-based dough

- Fully automated processing from dough preparation to final drying

- Food-grade stainless steel construction for maximum hygiene

- Energy-efficient operation with low running costs

If you want to manufacture top-quality gluten-free pasta efficiently, our Rice Pasta Machine and complete Rice Pasta Processing Line offer the perfect solution for your business growth.

Benefits of Rice Pasta Making Machine

- Consistent Quality and Cooking Performance – Our system ensures that every batch of rice pasta maintains uniformity in texture, moisture, and cooking quality, boosting customer satisfaction.

- Highly Efficient and Cost-Effective Production – Thanks to automation, the Rice Pasta Making Machine minimizes labor costs and material wastage while maximizing output.

- Flexibility in Product Innovation – Easily switch molds and adjust recipes to produce different pasta shapes and types using the same setup.

- Safe and Hygienic Production – Manufactured using food-grade materials and designed for easy cleaning, ensuring the highest hygiene standards.

- Scalable for Business Growth – Our Rice Pasta Processing Line can be easily expanded as production requirements grow, making it a future-ready investment

Butterfly Pasta Processing Line

Our Butterfly Pasta Processing Line is designed for manufacturing butterfly-shaped pasta, commonly known as bow tie pasta or farfalle. This fully automated line handles everything from dough preparation to shaping, cutting, and drying.

The core of the line is the Butterfly Pasta Making Machine, which is specially engineered to form the unique pleated and pinched center design that characterizes bow tie pasta. Our processing line delivers premium-quality products ready for local and international markets.

Benefits of Rice Pasta Making Machine

Our Butterfly Pasta Processing Line provides significant advantages for manufacturers:

- Produce Authentic Butterfly, Bow Tie, and Farfalle Pasta – Our Bow Tie Pasta Machine and Farfalle Pasta Making Machine are optimized to create the traditional pinched design and perfect texture that consumers expect.

- High Efficiency and Consistent Output – The line ensures that every piece of pasta has the right thickness, shape, and finish, helping brands maintain premium quality standards.

- Cost-Effective and Scalable – Our system minimizes wastage, reduces labor costs, and can scale up production to meet growing market demand.

- Hygienic and Easy to Maintain – Built from food-grade materials, our Butterfly Pasta Making Machine ensures food safety and simplifies cleaning and maintenance tasks.

- Expand Your Product Range Easily – With the same line, you can diversify into other shaped pasta products, making it a smart investment for future growth.

Whether you’re launching a new pasta brand or expanding your production capabilities, our Butterfly Pasta Machine, Farfalle Pasta Machine, and complete processing line provide the perfect solution for high-quality butterfly pasta production.

Gnocchi Pasta Processing Line

Our Gnocchi Pasta Processing Line is designed to produce high-quality gnocchi pasta with a soft, pillowy texture and traditional shape. The line offers fully automated processing from dough preparation to final packaging, ensuring consistency and high output with every batch. At the core of the line is our specialized Gnocchi Pasta Making Machine, which is engineered to handle delicate potato-based dough, shaping and cutting it into perfect gnocchi pieces. Whether you’re producing fresh or frozen gnocchi, our line guarantees exceptional product quality with every cycle.

Key Features of the Gnocchi Pasta Making Machine

- Advanced Gnocchi Pasta Machine for precise shaping and cutting of gnocchi

- Fully automated line for efficient, large-scale production

- Food-grade stainless steel construction for maximum hygiene and durability

- Easy-to-change molds for different gnocchi sizes and shapes

- Energy-efficient operation, minimizing operating costs

- Simple integration with drying and packaging systems

Benefits of Gnocchi Pasta Making Machine

Our Gnocchi Pasta Processing Line provides numerous advantages for pasta manufacturers:

- Consistent Quality and Shape – The automated process guarantees consistent dough handling, shaping, and cutting, ensuring high-quality gnocchi every time.

- Efficient and High-Volume Production – This line is designed for high-volume production with minimal labor costs, ensuring cost-effective manufacturing.

- Adaptable to Different Recipes – With easy mold adjustments, the Gnocchi Pasta Making Machine allows manufacturers to experiment with different recipes and flavors to meet market trends.

- Cost-Effective and Scalable – Our system minimizes material wastage and labor costs, while being scalable to accommodate increased demand as your business grows.

Whether you’re looking to introduce gnocchi into your product lineup or expand your existing pasta production, our Gnocchi Pasta Making Machine and processing line offer the ideal solution for efficient, high-quality production.

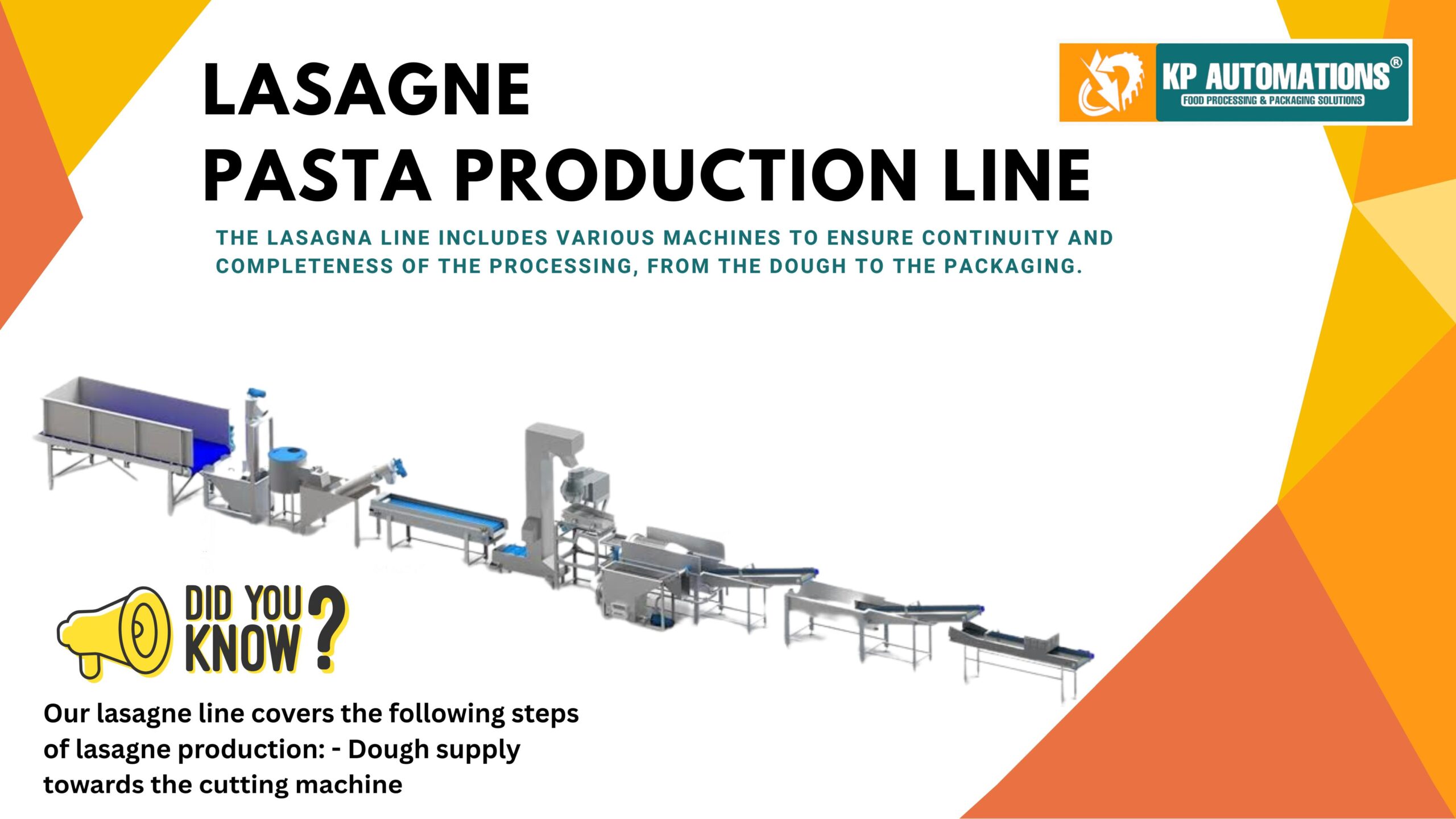

Lasagne Pasta Processing Line

Our Lasagne Pasta Production Line is crafted to meet the demands of high-quality lasagna sheet production, ensuring every piece comes out perfect, whether for home kitchens or commercial use.

Our advanced Lasagne Pasta Machine, designed to make the delicate task of shaping and cutting lasagna sheets a seamless process.

With adjustable settings for varying thickness and texture, the Lasagna Pasta Line is perfect for producing a range of lasagna sheet sizes, making it ideal for businesses that need both flexibility and efficiency.

Key Features of the Lasagne Pasta Making Machine

The Lasagne Pasta Machine provides consistent, high-quality sheet production with every cycle

- Fully automated for hassle-free, high-volume pasta manufacturing

- Adjustable controls for precise sheet thickness and size customization

- Crafted from food-grade stainless steel for hygiene and longevity

- Energy-efficient design to keep your costs low while maximizing output

- Easy integration with drying and packaging systems to complete the process

For those looking to streamline lasagna sheet production without compromising on quality, our Lasagna Pasta Line and Pasta Making Machine offer the perfect solution to meet your needs.

Ideal Applications of Lasagne Pasta Making Machine

The Lasagne Pasta Production Line is ideal for:

- Large-scale production of fresh and frozen lasagna sheets

- Supplying pasta for foodservice, restaurants, and retail

- Customizable pasta sheet thickness for various ‘ culinary needs

Whether you’re scaling up your production or offering specialized lasagna sheets, this line adapts to various market requirements.

Instant Pasta Processing Line

Our Instant Pasta Production Line is designed to meet the growing demand for high-quality, quick-cooking pasta and noodles. Whether you’re producing instant pasta or iconic instant noodles like Maggi, this fully automated line ensures high efficiency, exceptional product quality, and consistent output every time.

At the core of the system is our advanced Instant Pasta Making Machine, engineered to handle everything from dough mixing to shaping and cutting. This line allows manufacturers to produce a wide variety of instant pasta and noodles, providing flexibility while maintaining a fast production speed.

Key Application of the Instant Pasta Making Machine

The Instant Pasta Production Line is ideal for:

- Mass production of instant pasta, noodles, and Maggi-style products

- Supplying the growing demand for fast – cooking pasta in retail and food service

This line is perfect for companies looking to streamline their instant pasta production, with flexibility built in to meet different consumer demands.

Benefits of Instant Pasta Making Machine

Here’s why manufacturers should consider the Instant Pasta Production Line for their business:

- High-Speed Production – The Instant Pasta Machine is optimized for quick production, making it perfect for meeting the fast turnaround times that instant pasta and noodle markets demand.

- Consistent Quality – With precise control over the entire production process, you can ensure each batch of pasta or noodles is produced to the highest quality standards, every time.

- Built for Hygiene and Easy Maintenance – Made from food-grade materials, our Instant Noodle Making Machine is designed with food safety in mind and is easy to maintain, ensuring compliance with all industry regulations.

- Energy Efficiency – The energy-efficient design reduces operating costs while maximizing production output, helping you maintain profitability without compromising on quality.

Our Instant Pasta Production Line and Instant Pasta Making Machine are the ideal solutions for companies looking to tap into the growing market of instant pasta and noodles. With high-speed production, flexibility, and cost- effectiveness, this line provides a competitive edge in today’s fast-paced food industry.

Couscous Pasta Processing Line

Our Couscous Pasta Production Line is designed to deliver high-quality couscous at scale.

Whether you’re making traditional couscous or innovative variations, this fully automated line guarantees efficiency, consistency, and exceptional product quality.

The Couscous Pasta Making Machine integrates seamlessly into the production process, offering precision and versatility.

Manufacturers can rely on this system to meet both high output demands and maintain quality, ensuring customers get the best couscous every time.

Key Features of the Couscous Pasta Making Machine

- Couscous Pasta Machine designed for smooth and uniform granule production, ensuring every batch meets the highest standards

- Automated operations reduce manual labor and allow for continuous, high-volume production

- Easily adjustable settings allow for fine-tuning the granule size and texture, providing a customized product

- Made with food-grade stainless steel, the system ensures compliance with hygiene standards and durability

Benefits of Couscous Pasta Making Machine

- Optimized for Large-Scale Production – This automated line can handle large volumes of couscous production, ensuring faster output without compromising on quality, making it ideal for high-demand markets.

- Cost-Effective Production – With its energy-efficient design and automated processes, the line reduces labor and energy costs while boosting production efficiency, giving you better profitability.

- Seamless Production Flow – The Couscous Pasta Line integrates with drying and packaging systems, creating a smooth, uninterrupted production cycle from start to finish.

The Couscous Pasta Production Line offers the perfect solution for manufacturers looking to produce high-quality couscous with minimal effort and maximum output