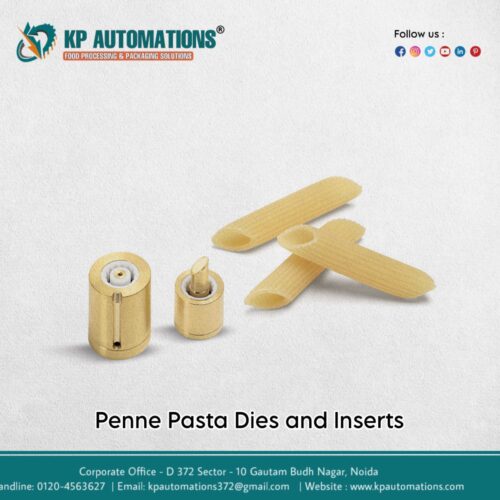

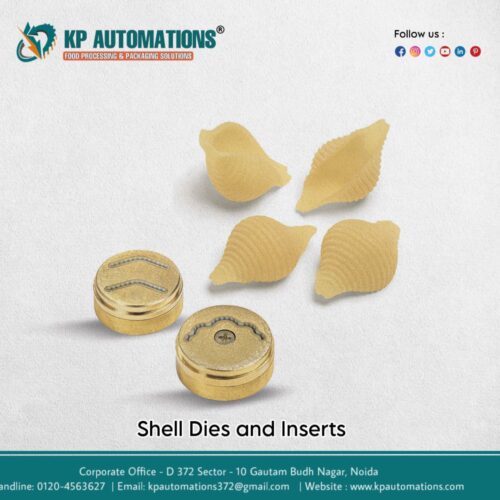

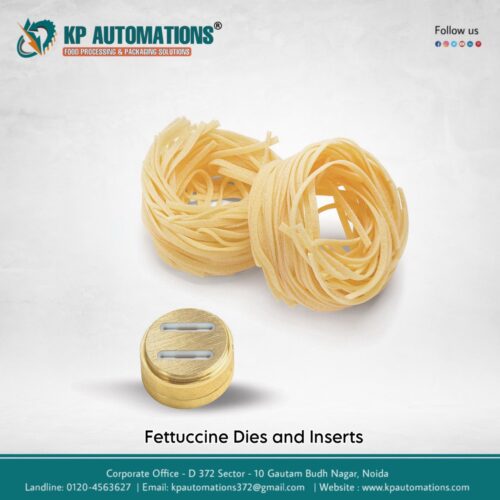

Pasta Dies and Mould Inserts: Precision in Pasta Production

Pasta dies and mould inserts play a crucial role in shaping pasta into various forms, ensuring consistency, quality, and texture. These components are attached to pasta extruders, allowing manufacturers to produce different pasta shapes such as penne, fusilli, macaroni, spaghetti, and farfalle. High-quality dies, typically made from bronze or Teflon, impact the pasta’s surface texture—bronze dies create a rough, porous texture ideal for holding sauces, while Teflon dies produce smooth and glossy pasta.

The choice of pasta die and mould insert determines the efficiency of production and the final product’s appeal. Customizable die designs enable manufacturers to experiment with unique pasta shapes, catering to consumer preferences and market trends. Advanced pasta dies are engineered for durability and precision, ensuring uniform pasta thickness and reducing production waste. Proper maintenance and timely replacement of mould inserts enhance the lifespan of pasta machines and maintain optimal output quality.

For commercial pasta producers, investing in premium pasta dies and mould inserts is essential for product diversification, brand distinction, and superior texture quality. Whether producing traditional Italian pasta or innovative gluten-free variants, the right die selection ensures efficiency, consistency, and a high-quality end product that meets consumers expectations. Capable of producing pastas ranging from 50Kg/hr – 5000kg/hr.