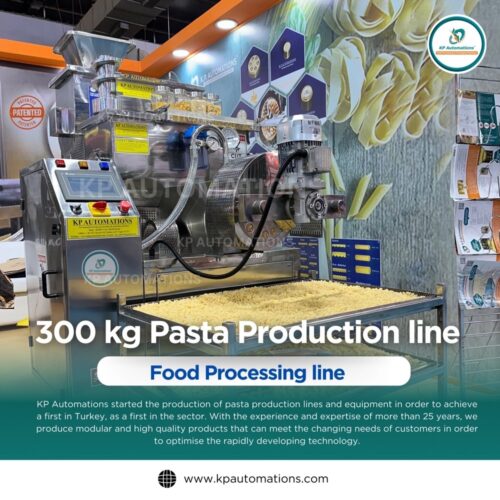

The best technology in pasta production

Short-cut pasta is produced with the short-cut production line produced in accordance with the modular system and technology. Water, semolina or flour are used as raw materials in short cut pasta lines.With the help of molds and equipment designed in accordance with the purpose of the line, it enables the production of pasta in different shapes and thicknesses in accordance with the demands and needs of the customers. Line management is provided by “PLC Control System”. Capable of producing pasta from 50Kg to 5000kg/hr.

Pasta production line ranging from 50kg/hr to 5000kg/hr

Short-cut pasta lines use water, semolina or flour as raw materials.

With the help of equipment designed in accordance with the purpose of the line, pasta is produced in different lengths and thicknesses according to the wishes and needs of the customers.